Background: I’m using the generic data model because my subnetwork device needs to be the one to initiate a consume (by Anybus) transaction. A consume transaction contains the results of a measurement my device takes. (Measurement here is not a continuous thing like temperature from a sensor, but a process that starts and ends after several seconds, does a calculation, then sends result data to the PLC via Anybus. The next measurement is started, etc.)

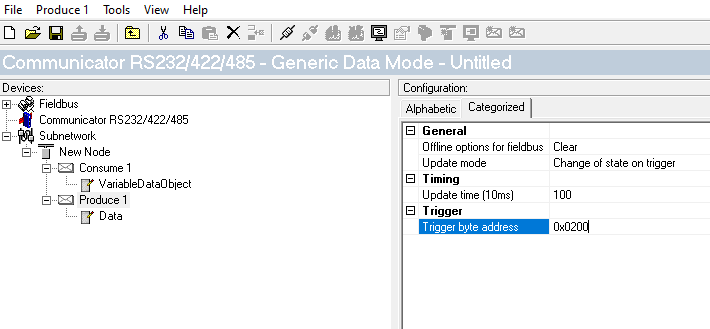

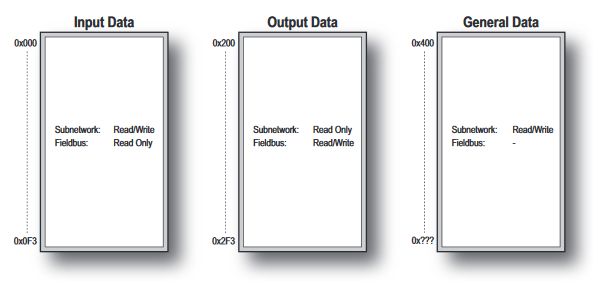

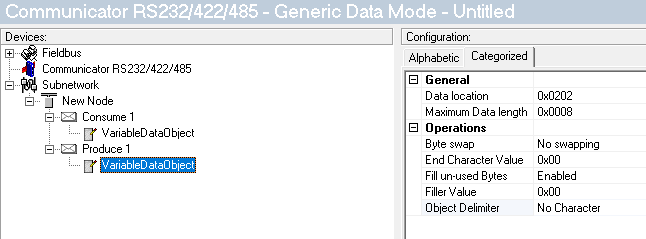

In response to receiving the measurement data, the PLC will change data at an address in Anybus, whose change of state prompts a subnetwork produce transaction (the PLC’s ACK reply). Fine

But my question is, how can my subnetwork device, whenever it wants, prompt the same (subnetwork) produce transaction to be able to read the value of that register the PLC writes to?

That is, if I have doubts that I missed the initial subnetwork produce transaction prompted by the (one shot) change-of-state, How can the subnetwork prompt a re-check of the value of that output memory register?