It is not clear to me what Modbus registers in the AB7808-F I need to query from my Modbus master to retrieve the data from a Profibus DP device. Profibus device is E+H FMU95 with 10 ultrasonic level sensors attached. Just need to read those 10 level values from AB7808-F Modbus registers.

I got the GSD file for the E+H device and used the Anybus NetTool for PROFIBUS to configure the 10 slots with AI(OUT) - not sure if this correct but there really is no other action I can do.

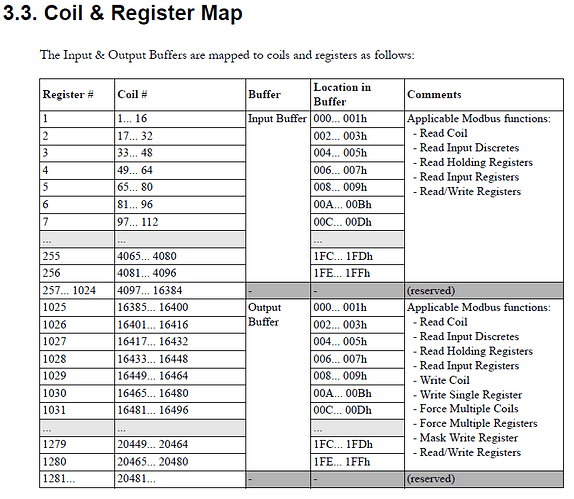

Here is the Modbus map from the Anybus Modbus RTU Network manual.

I don’t understand the correlation between the “input address” shown in Anybus NetTool and the Modbus map in the manual.