Good afternoon,

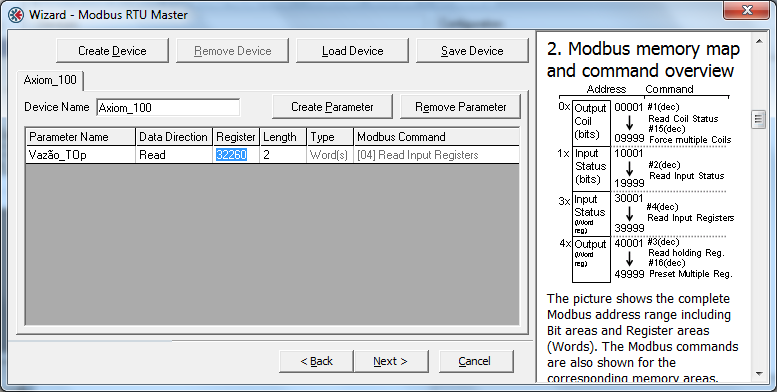

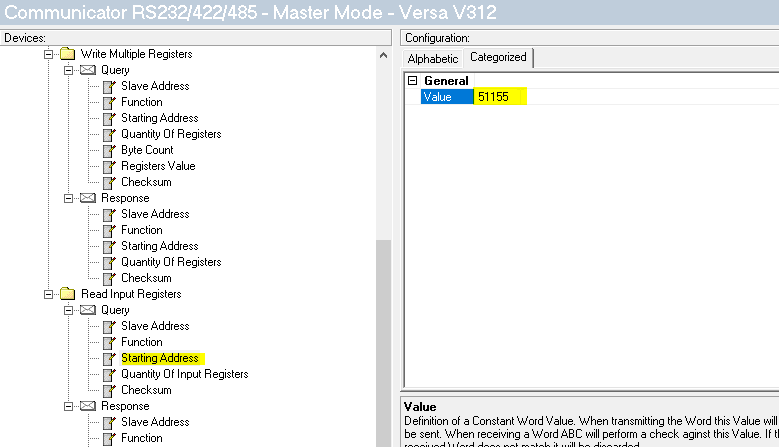

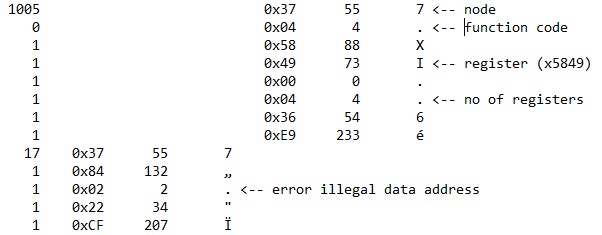

I have a problem where I don’t need to integrate my anybus AB7000-C with an ethanol loading flow computer, but I can’t insert the modbus addresses into anybus, because they have an extra number next to the function.

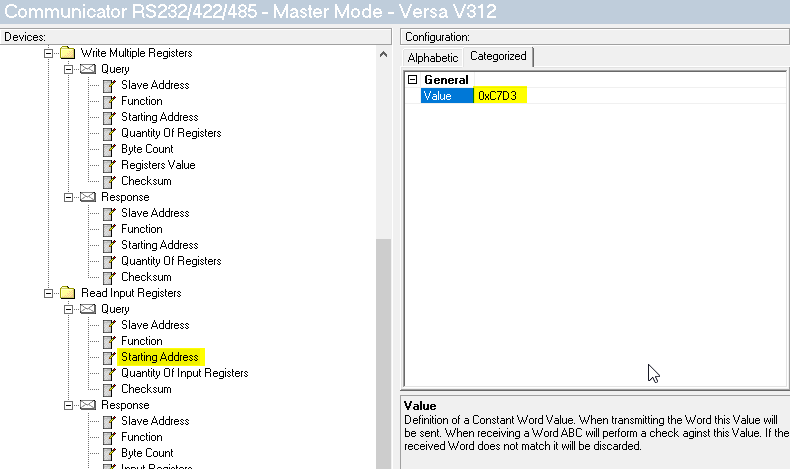

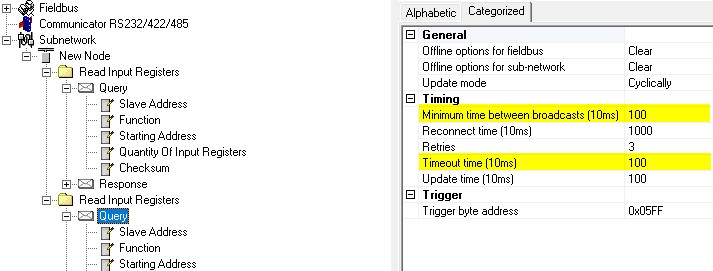

Below is the anybus configuration manager

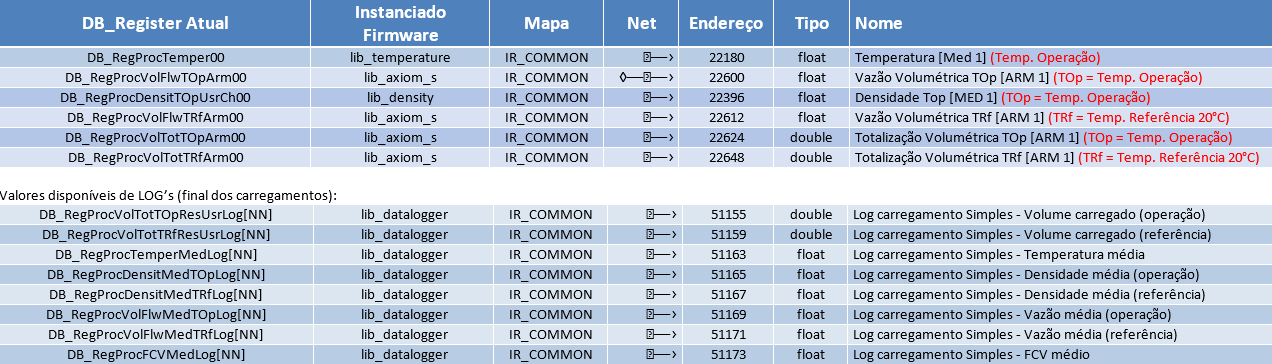

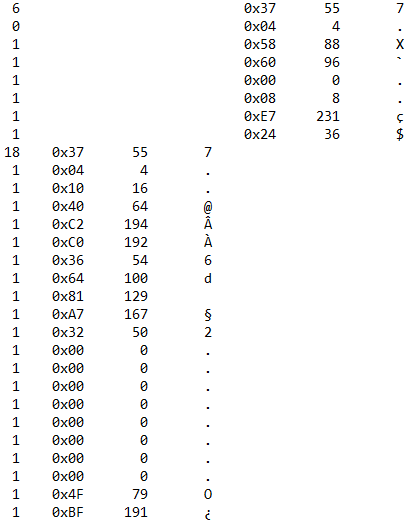

Below are some variable addresses to be read

|22180 float Temperatura [Med 1] (Temp. Operação)

22600 float Vazão Volumétrica TOp [ARM 1] (TOp = Temp. Operação)|

22396 float Densidade Top [MED 1] (TOp = Temp. Operação)|

22612 float Vazão Volumétrica TRf [ARM 1] (TRf = Temp. Referência 20°C)|

22624 double Totalização Volumétrica TOp [ARM 1] (TOp = Temp. Operação)|

22648 double Totalização Volumétrica TRf [ARM 1] (TRf = Temp. Referência 20°C)|

I’m very grateful if you can help us.

graciously;

Maike.