Kyle,

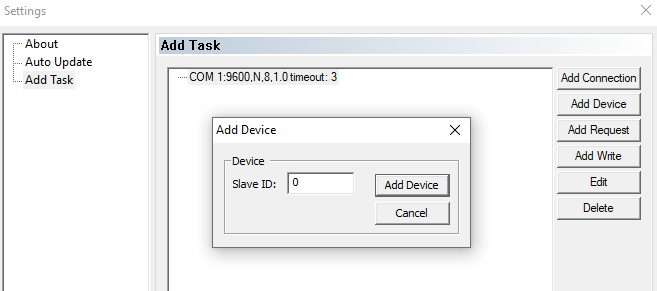

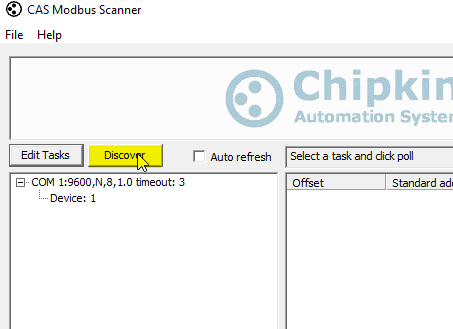

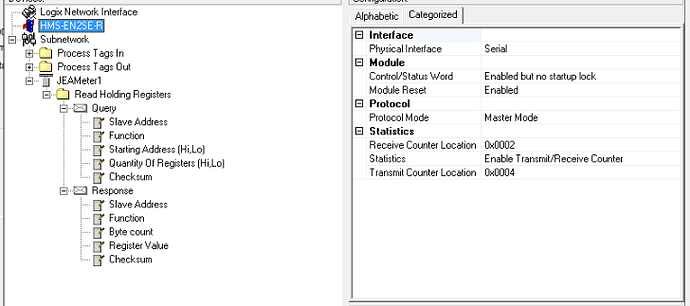

I have reconfigured this system to use a local CompactLogix CPU to connect to the HMS gateway. The CPU seems to communicate correctly, but I am still having difficulty with the ModBUS side. I used CAS Modbus scanner to connect to the modbus device locally,

and here is the series of messages I received while trying to read coils, inputs regs, holding regs, and status regs:

"[14:16:44] Recv error: Exception Response:

The device responded but with an error instead of data

0x02 - ILLEGAL DATA ADDRESS

The data address sent in the query is not an allowable address for the server (or slave). More specifically, the combination of reference number and transfer length is invalid. For a controller with 100 registers, a request with offset 96 and length 4

would succeed, a request with offset 96 and length 5 will generate exception 02. A request for offset 200 will also produce this exception.

[14:16:11] <= Response: 01 84 02 C2 C1

[14:16:10] => Poll: 01 04 00 00 00 0A 70 0D

[14:16:06] Recv error: Exception Response:

The device responded but with an error instead of data

0x02 - ILLEGAL DATA ADDRESS

The data address sent in the query is not an allowable address for the server (or slave). More specifically, the combination of reference number and transfer length is invalid. For a controller with 100 registers, a request with offset 96 and length 4

would succeed, a request with offset 96 and length 5 will generate exception 02. A request for offset 200 will also produce this exception.

[14:15:59] <= Response: 01 83 02 C0 F1

[14:15:58] => Poll: 01 03 00 00 00 02 C4 0B

[14:15:53] Recv error: Exception Response:

The device responded but with an error instead of data

0x02 - ILLEGAL DATA ADDRESS

The data address sent in the query is not an allowable address for the server (or slave). More specifically, the combination of reference number and transfer length is invalid. For a controller with 100 registers, a request with offset 96 and length 4

would succeed, a request with offset 96 and length 5 will generate exception 02. A request for offset 200 will also produce this exception.

[14:15:46] <= Response: 01 82 02 C1 61

[14:15:46] => Poll: 01 02 00 00 00 02 F9 CB

[14:15:46] Connect to COM 4:9600,N,8,1.0 timeout: 3

[14:15:36] Ready…

[14:15:36] Starting up…"

Can you make any sense of this?

Thanks,

Ross

This message may include restricted, legally privileged, and/or confidential information. If you received this message by mistake please delete it immediately and inform us about it. This message will be considered as originated from Gerdau or its subsidiaries

only when formally confirmed by its officers authorized for that.

Este mensaje puede contener informaciones de uso restringido y/o legalmente protegido. Si usted ha recibido este mensaje por error, por favor eliminelo e informe de tal situación al remitente. Este mensaje solamente será considerado como proveniente de Gerdau

o de sus subsidiarias cuando sea confirmado formalmente a través de los representantes legales debidamente autorizados para tal fin.