From my customer:

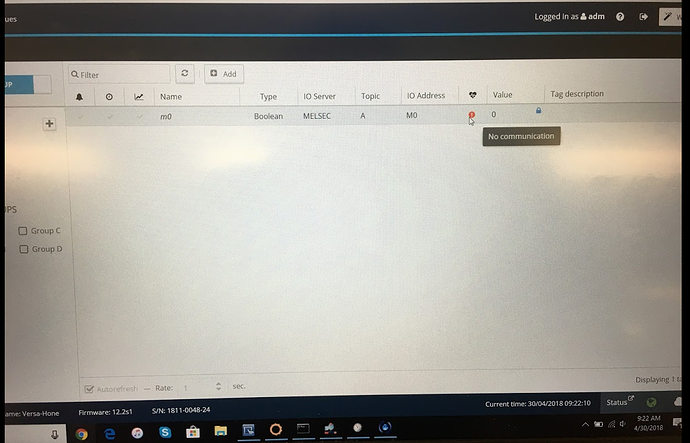

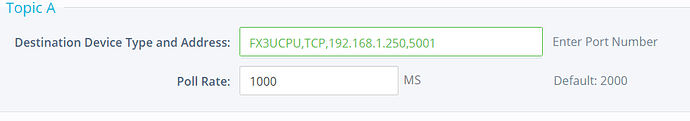

I am using a Mitsubishi FX3U processor with an Ethernet adapter card. I’m getting communication errors when trying to read tags. In the EWON I am using the MELSEC I/O server and getting communication errors.

Backups moved to staff note

His IO Server config looks to be the same as the last reply in this thread: Mitsubishi FX3 to eWon flexy

But I don’t have a Mitsubishi PLC to test with unfortunately.

Any ideas?

Edit: He’s going through an N-Tron switch from Flexy to PLC