From customer:

Hi,

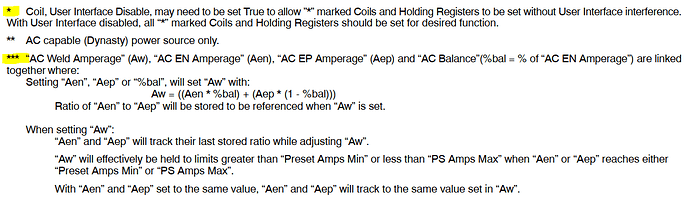

I am working with an Anybus Communication 7072. I am trying to connect an industrial robot to a tig welder. my robot has ethernet/ip scanner/adapter and the welder has modbus rtu (RS 485). I have spent about 3 days trying have any sort of communication between the AB7072 and the welder. Robot to AB7072 via Ethernet/IP was quick and easy but modbus portion not so much. I have tried multiple things with no luck. if there is a way to get even a ping across to make sure i am communicating, then i can use that to start mapping my data. While doing some research, i came across a document that said that resistors were to be placed on the master side and the slave side. if this is true, what value of resistor should i use? (60, 120, 470 ohm are the common ones i have seen) Any help is much appreciated.

Best Regards

Josey