Hi,

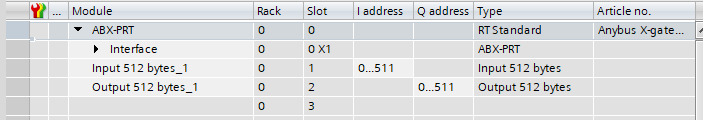

We’re working on setting up a AB7670 between a Siemens S7 1500 using TIA Portal, and a vision system that is presenting its data as a Ethernet/IP device.

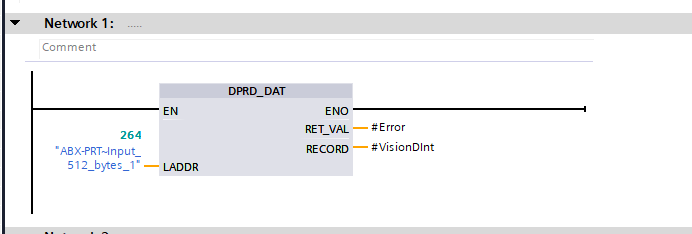

We have communications working, but the vision system is outputting its data as DINT values (32 bit integers) and the Siemens is reading it as bytes. We appear to be getting data tearing issues when we combine the DINT values again on the PLC.

The test we ran was as follows: we output a series of 32 bit values as DINT which have 4 identical and incrementing bytes, when we get the bytes and reassemble them, the higher number bytes on the PLC occasionally are from a later DINT (as they are higher). (Put another way we output 0x01010101, then 0x02020202, then 0x03030303, and occasionally received 0x02020303, for example).

How can we get synchronized multibyte data through this gateway?

Thanks.