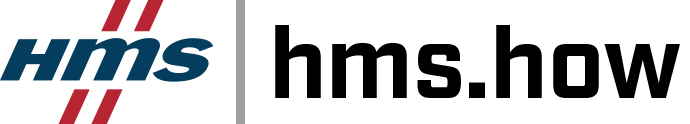

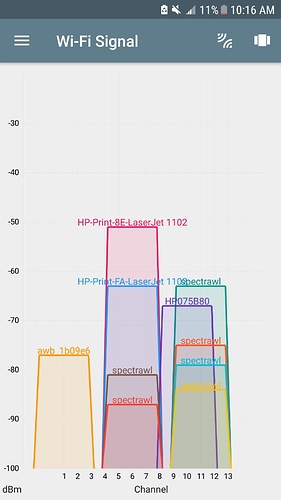

There is a lot of confusion regarding channel usage especially in the 2.4GHz band of WLAN, the channels are 5MHz apart from each other, but each channel uses 20/22MHz bandwidth depending on modulation.

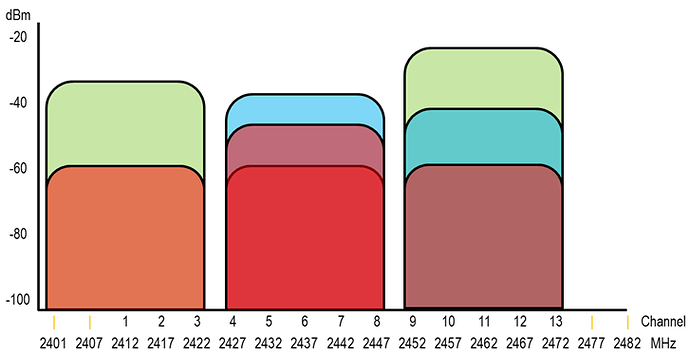

In the below example you can see 2 SSID:s using ch1, 1 using ch3, 2 using ch6 and 3 using ch11. In this setup 1, 3 and 6 will have a very bad performance with a lot of resends due to bad packages, channel 11 though should be ok.

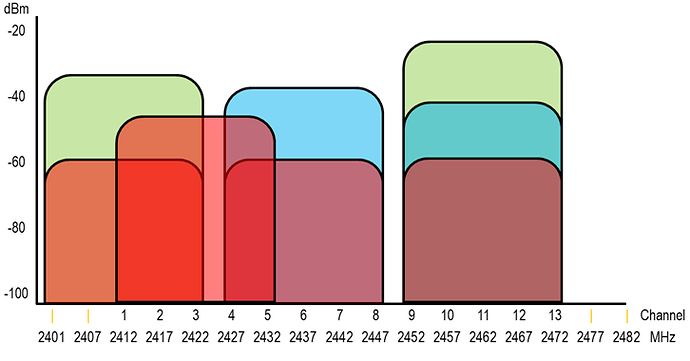

But by changing the SSID on ch3 to either 1, 6 or 11 the problem would be gone. During normal usage the data usage in a network comes in bursts, when you open or save a file to a server or browsing the web, it is only when downloading very big files or streaming video in a high quality that the bandwidth is being used.

My point, the channels are not occupied that much in normal conditions, and as the WLAN is checking if the channel is occupied before sending the data, multiple SSID:s can share the same channel.

More info on CSMA/CA -

https://en.wikipedia.org/wiki/Carrier-sense_multiple_access_with_collision_avoidance

There are numerous good sources of information regarding channel usage and other best practice example, a good one can be found at

https://www.metageek.com/training/resources/why-channels-1-6-11.html they also manufacture the WiSpy spectrum analyzer that is needed for anyone working with WLAN:s to detect disturbances that are not originating from other WLAN:s but different RF sources (Motion detectors, Industrial remote control, Microwave ovens and so on)