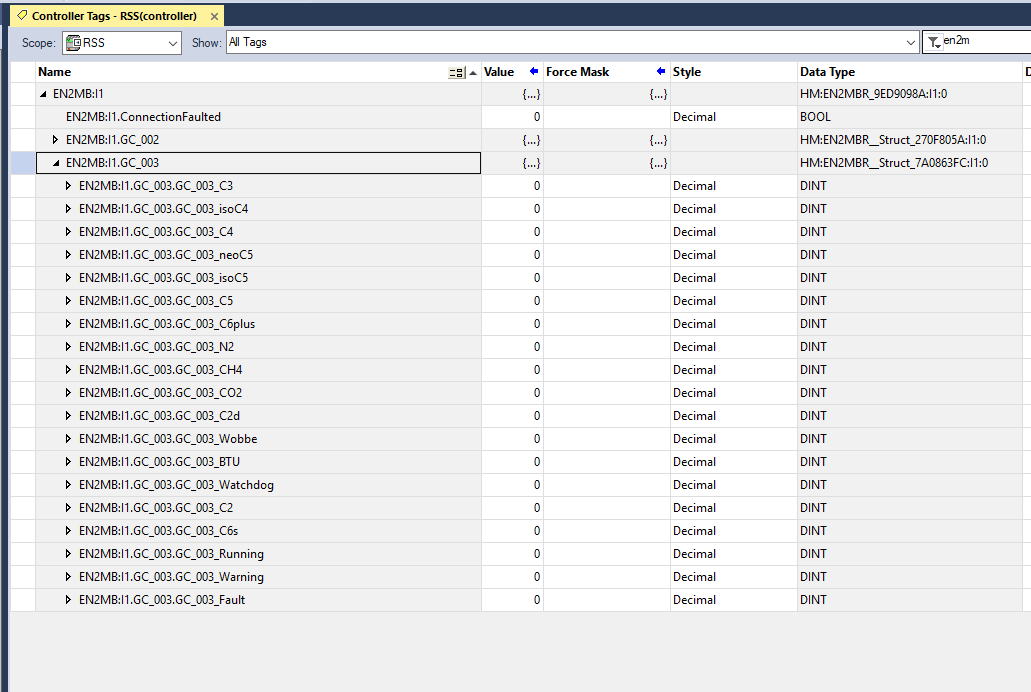

OK… here is the original issue…

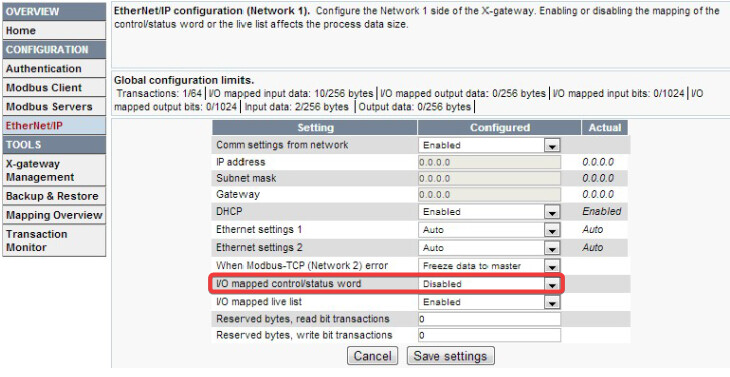

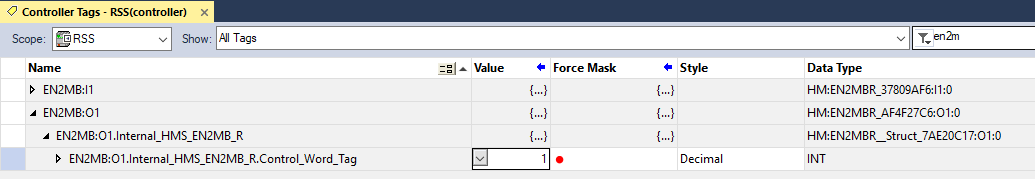

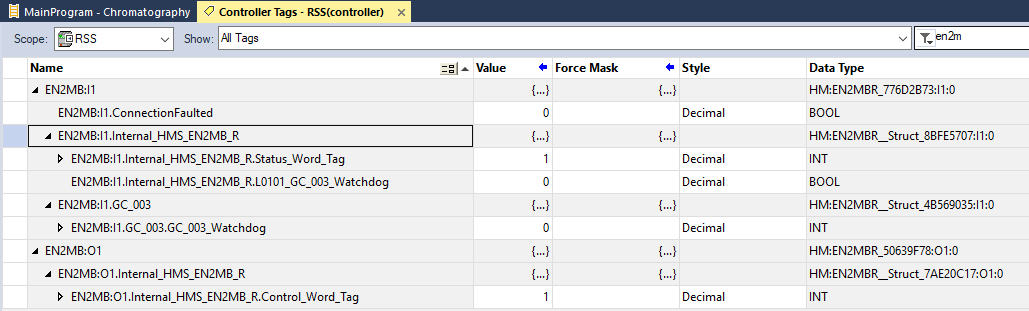

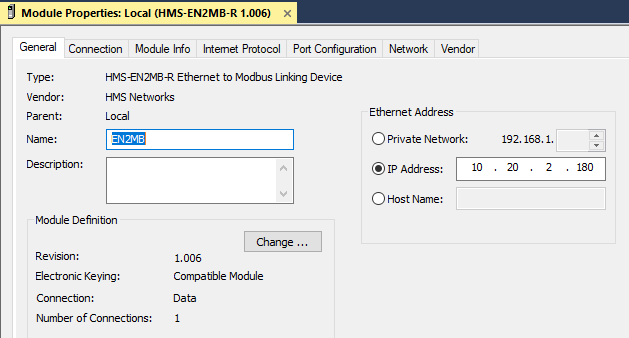

I found the Control Word setting in the EN2MB dialog box was Disabled, so I enabled it and downloaded the new configuration from the EN2MB to the PLC and downloaded that new program change into the PLC. I went into the PLC and changed the control word from a zero to a one.

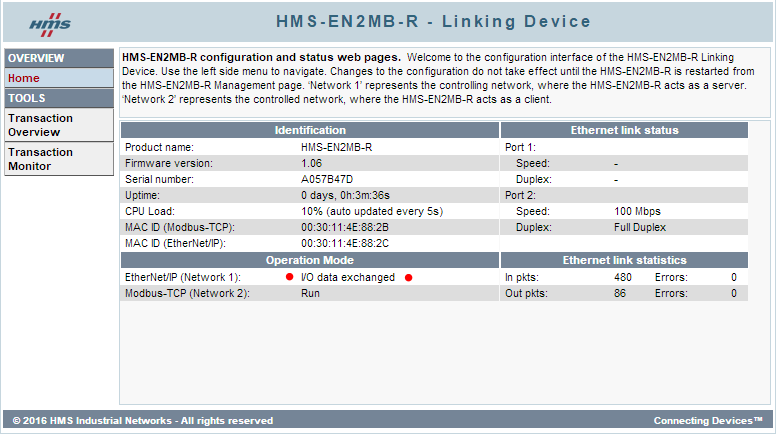

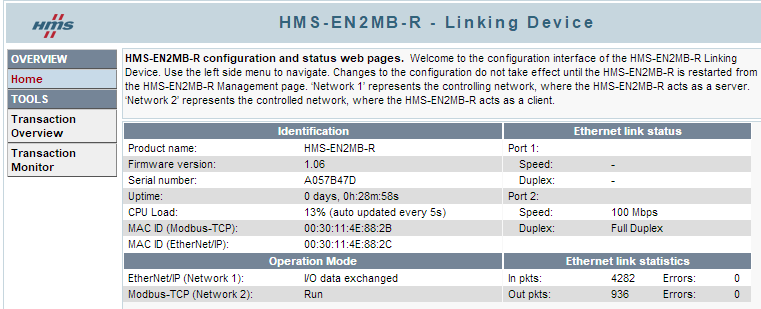

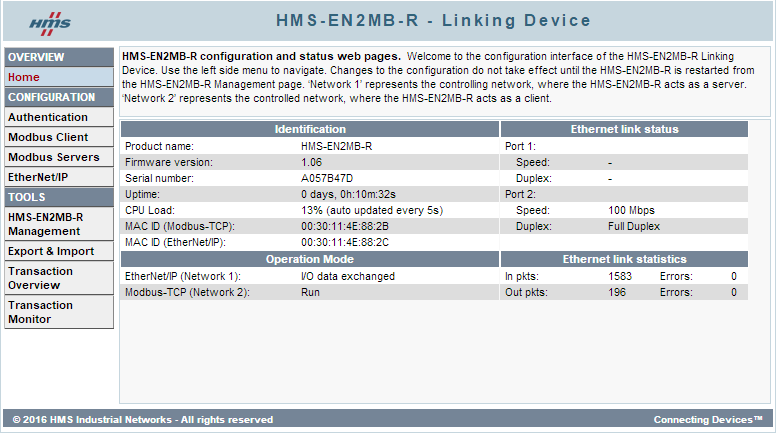

Looking at the HMS, it now appeared that the PLC was communicating with the EN2MB, as the message used to report that Data was NOT being exchanged.

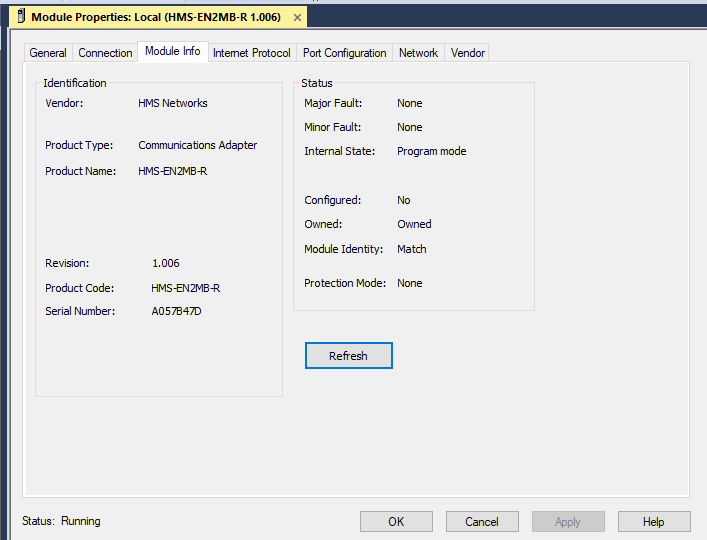

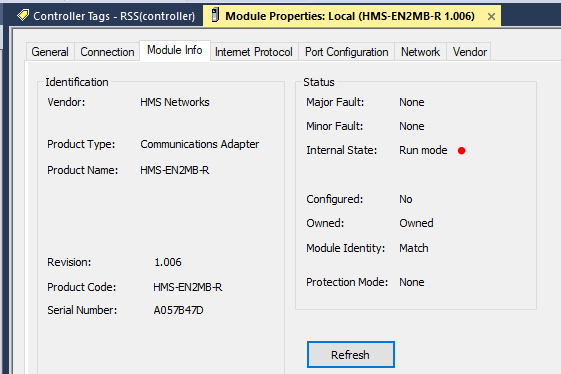

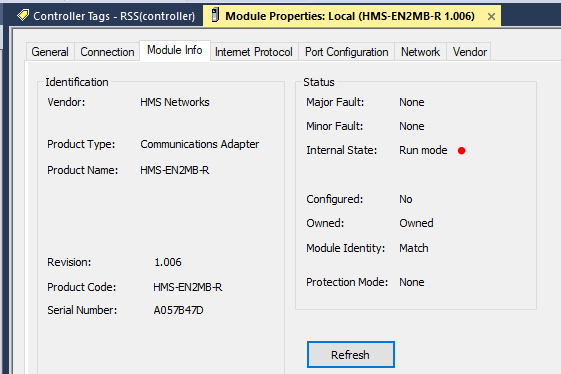

Checking the EN2B Properties Panel is Studio 5000 new showed me that the EN2B was in Run Mode.

So that answers my original question and gets me closer… BUT I still get no data transfer.

We should probably consider this a second issue to solve.

ISSUE 2:

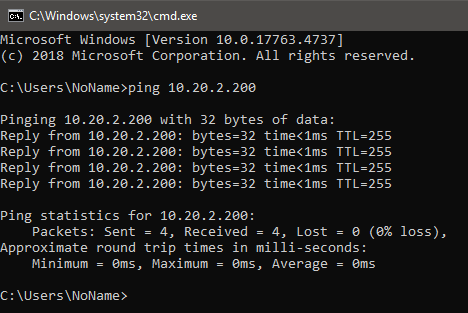

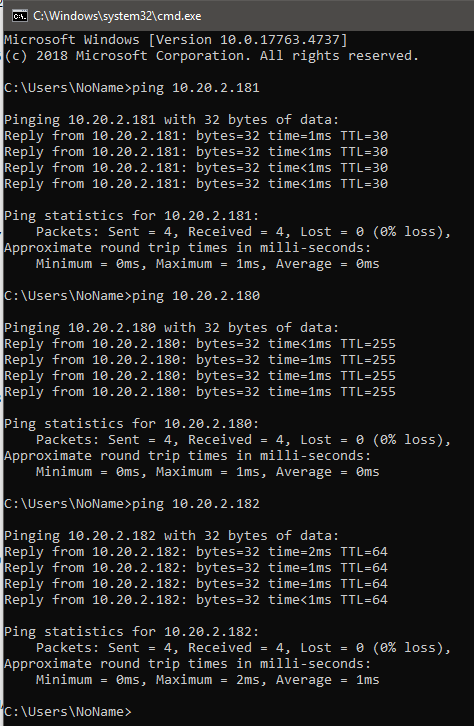

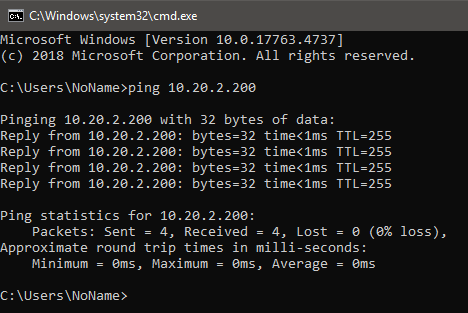

I have power applied and it has booted up. I can ping the EN2MB from the LAN:

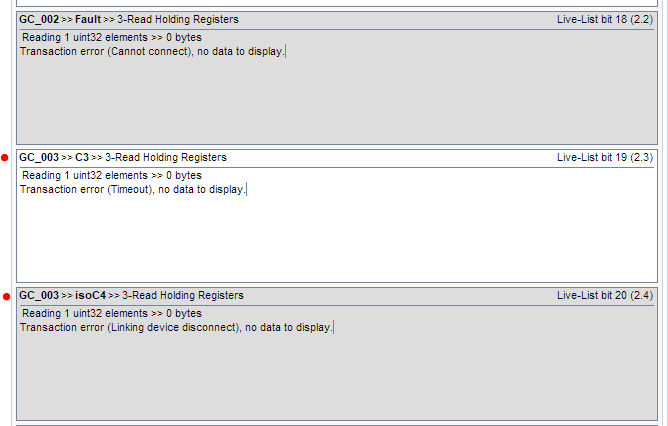

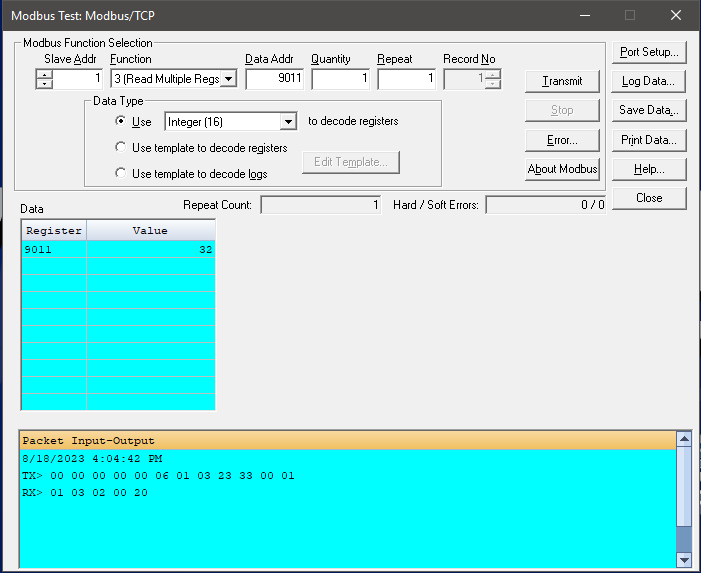

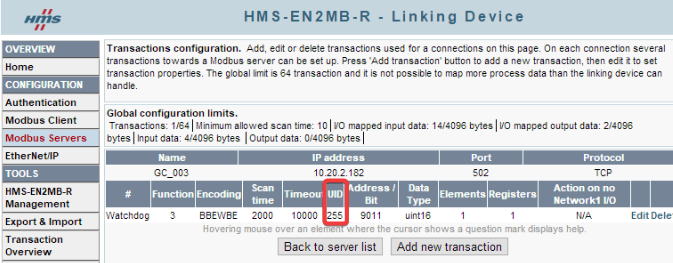

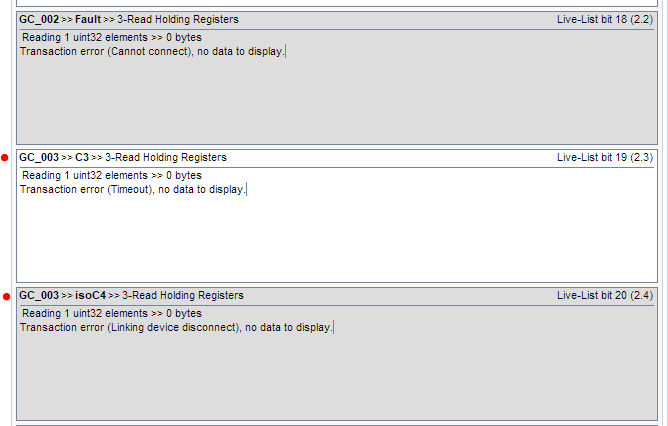

However, the Transaction Monitor is still insistent that there is a “Timeout”. After the timeout, all subsequent transactions describe the Linking Device as having disconnected.

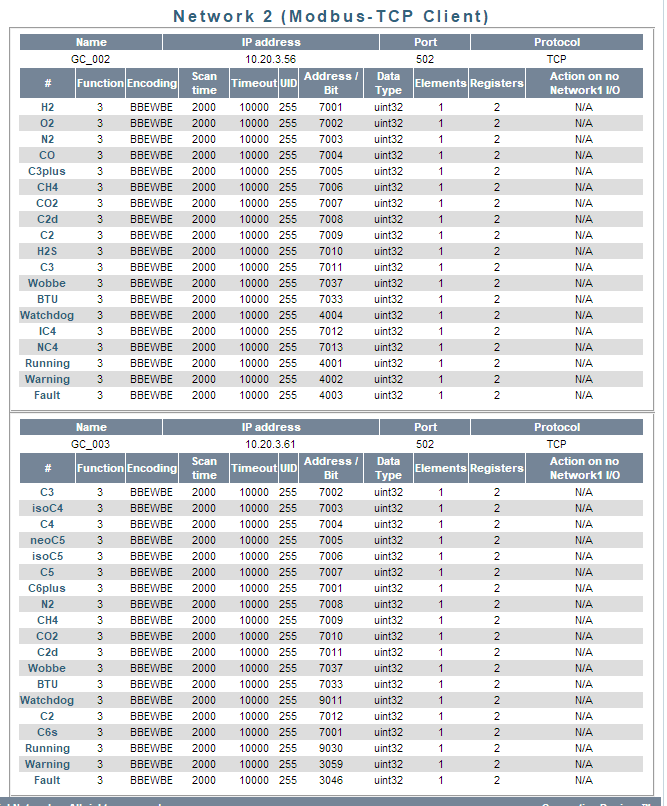

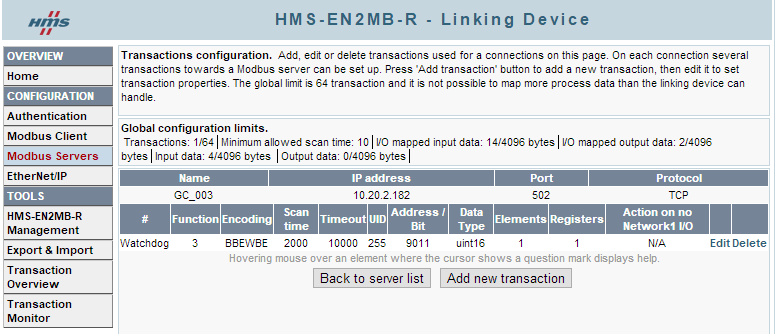

I don’t know if this means that the PLC is not able to read from the EN2MB or if the EN2MB is not able to read from the 370XA. In my Modbus Configuration, I have two devices. GC_002 has now power or wiring to it yet, so there’s no surprise that I cannot connect to it. However, GC_003 (the 370XA) has power, and is able to be pinged on its own subnet as 10.20.3.61.

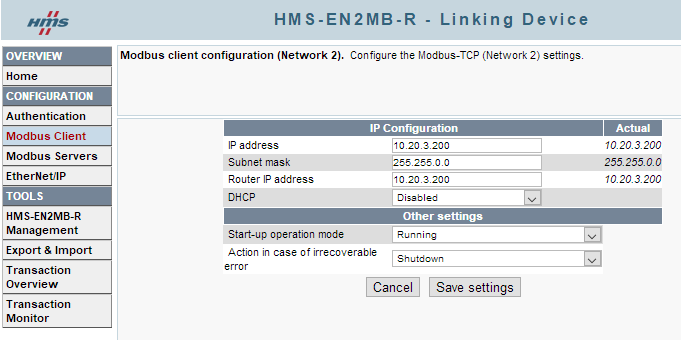

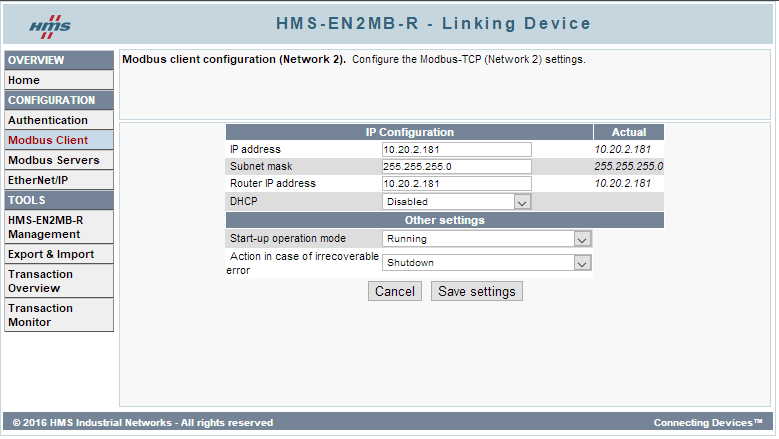

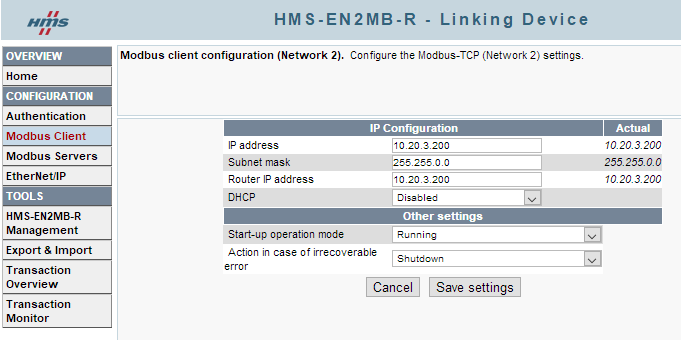

Perhaps I have the EN2MB set up incorrectly as far as being able to cross over the two distinct subnets of 10.20.2.xxx and 10.20.3.xxx, but I think I have it set up the same as the system that works.

Let me know what else I could show you that might lead me to a solution.

Thanks! (looks like progress to me so far!)